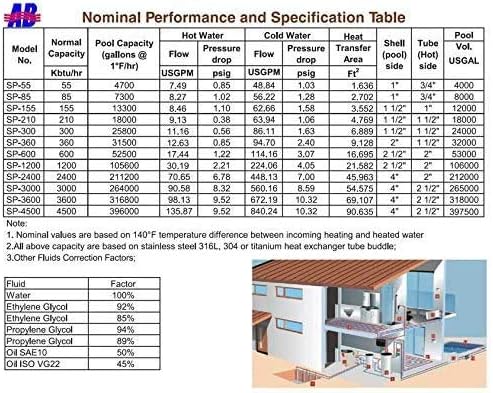

AB Pool Heat Exchanger: 360 kBtu Stainless Steel 316L Opposite Ports 2" & 1 1/2" FPT for Spa/Solar/Swimming Heating and Cooling

Fully made of high grade anti-corrosion stainless steel 316L for swimming pool, spa, hot tub with chemical treatment.

1 year warranty to cover

-

Detail

Customer First, Integrity, and Mutual Success

Shell and tube heat exchanger is the most typical dividing wall type heat exchanger, its application in the industry has a long history, and it still occupies a dominant position in all heat exchangers.

A shell and tube heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The wall of the tube bundle is the heat transfer surface.

An essential component for swimming pool heating systems and other water heating applications, Swimming Pool Heat Exchangers are designed to maximize water heating efficiency and save money and energy.

Note:

It is recommended maximum chloride concentration in fresh/clear water inside the heat exchanger under 140℉ is considered to be: 300 mg/L. When water temperature increases, the maximum chloride concentration should decrease.

Above the recommended concentration of chloride and/or directly use a chlorinator might induce pitting of 316L stainless steel overtime. Titanium pool heat exchangers are recommended for environments with high chloride concentrations or saltwater systems.

A heat exchanger is a device that transfers part of the heat of a hot fluid to a cold liquid. Heat exchangers are general-purpose equipment in chemical, petroleum, power, food, and many other industrial sectors and play an important role in production.

There are many types of heat exchangers, but according to the principle and method of heat exchange between cold and hot fluids, they can be divided into partition type, hybrid type, and regenerative type. The partition wall heat exchanger is the most widely used among the three types of heat exchangers.

According to the shape and structure of the heat transfer surface, it can be divided into the shell and tube heat exchanger and plate heat exchanger.

Fluid Layout Instructions

In shell and tube heat exchangers, there is a potential for a tube to rupture and for high pressure (HP) fluid to enter and over-pressurize the heat exchanger's low pressure (LP) side. To avoid risk to people and financial loss, the usual configuration of exchangers is for the HP fluid to be in the tubes and LP water, cooling, or heating media to be on the shell side.

Please always install the heat exchanger in a counter flow pattern, as shown in the above picture. The heat exchanger should be installed downstream of the filtration and pumping equipment. The boiler water must be assisted and the usal precautions taken to prevent air locks. The pool water pump should be controlled by a thermostat in the pool pipe work before the heat exchanger and set at the required temperature.

Our Commitment

Shell and Tube Heat Exchanger

Stainless Steel 316L

About the Heat Excahnger

Precaution before Installation

-

Customer ReviewsNo comments